RANCHO CUCAMONGA, CA ( APRIL 6, 2004) — From Ground Zero to Operation Iraqi Freedom, Broco’s Prime-Cut® and GOWELD® products are seeing duty in the War on Terror. During the horrific hours following the 9/11 attacks on the World Trade Center, first responders used Prime-Cut® in rescue and recovery efforts. One year ago, the United States Marine Corps selected Prime-Cut® and GOWELD® for the Battlefield Welding and Cutting Kit (BWACK) that is required equipment on-board the M-88A2 Hercules Recovery Variant (tank recovery vehicle). The First and Second Marine Tank Battalions utilized GOWELD® and Prime-Cut® during Operation Iraqi Freedom. A Lance Corporal of Second Tank Battalion earned the Bronze Star for heroism in the face of direct fire using Prime-Cut® to restore mobility to a damaged tank on a bridge entering Baghdad. Today, the USMC, Ranger’s, Armored Cavalry, Special Forces, U. S. Navy and many foreign militaries are Broco® users. The BWACK is on display at the American Welding Society Show, April 6 – 8, in Chicago.“Broco® cutting and welding systems are sophisticated and strong enough for use on the redefined battlefield of the 21st century,” said Richard Ferry, president of Broco, Inc.® “GOWELD® and Prime-Cut® serve as workhorse tools for our industrial customers in a wide range of cutting and welding applications. Both our military and industrial customers benefit from our high-standard for toughness and appreciate the systems’ reliability and capabilities.”

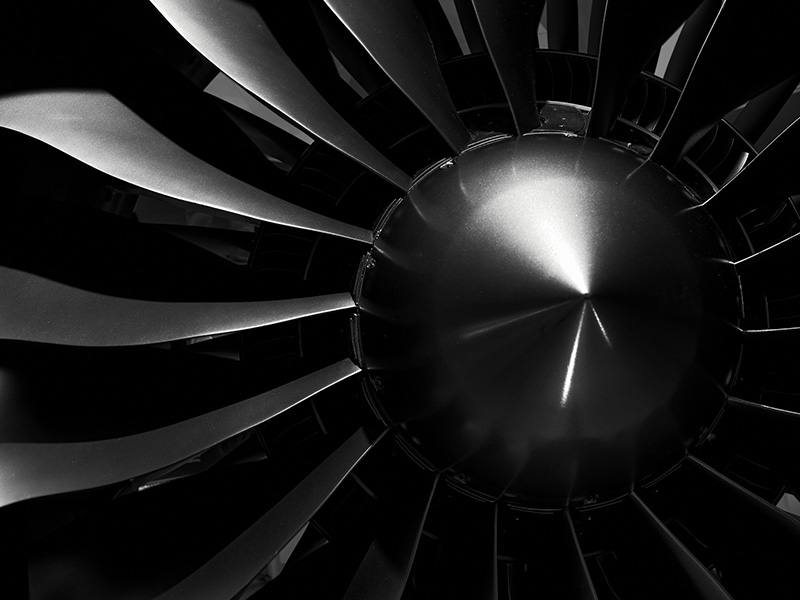

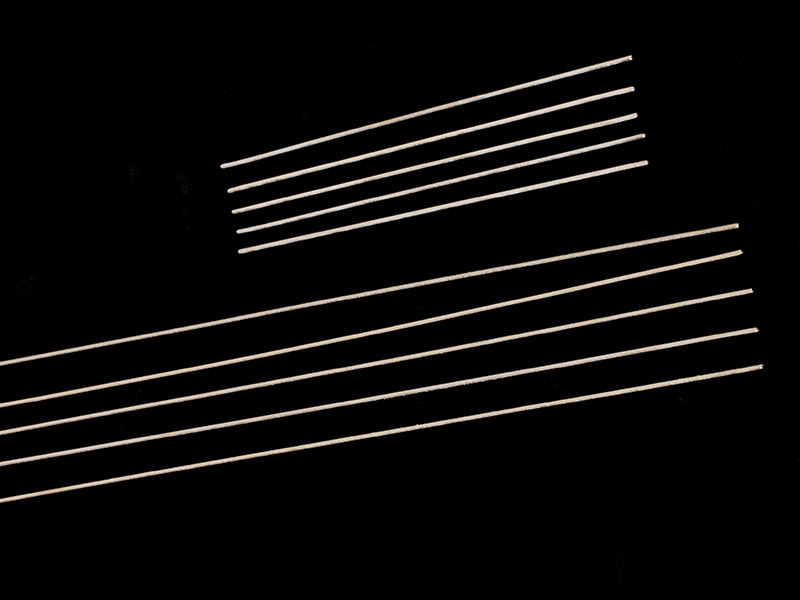

The BWACK kit includes GOWELD® portable battery-powered MIG welder, which was selected as the only welder on the Hercules, and Prime-Cut® Model PC-A5V2HR Backpack Cutting Set with Industrial Torch. Broco’s Prime-Cut® ultrathermic cutting system operates at temperatures in excess of 10,000 degrees Fahrenheit and easily cuts, gouges and pierces almost any known material including stainless steel, hardened steel, cast iron, concrete and more. Prime-Cut’s® simplicity of operation, high reliability, and power to cut through armor plate or track sections makes it a valued tool for the soldier, sailor, or marine.

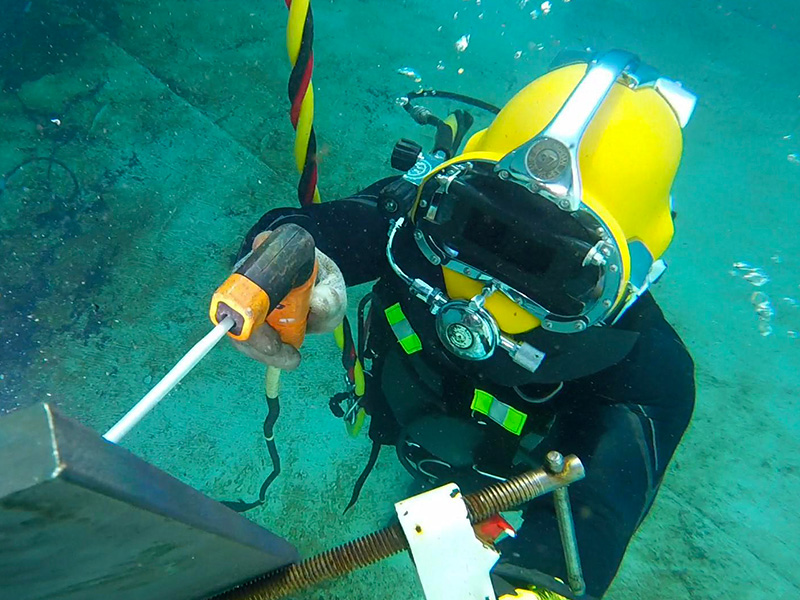

Prime-Cut® industrial applications include heavy equipment repair and maintenance for track and king pin removal, gouging to remove hardfacing and old welds, and removing bushings, bucket tooth shanks and edges. Plant maintenance professionals use the system topenetrate concrete pipes, install machinery anchor bolts and remove frozen bolts. Other industrial applications include demolition, shipboard damage control, cutting pipe and grout liners,

specialty cutting, piercing and more. Prime-Cut® is carried by first responders for fast, effective rescue and recovery operations.

GOWELD® was also tested and approved by the United States Army and is a part of the new Urban Ops Supplemental Toolkit which consists of key tools to support the needs of the armed forces in the redefined 21st century battlefield. GOWELD® and Prime-Cut® are also used in USMC M1A1 Tank maintenance training courses.

“Professionals and do-it-yourselfers find GOWELD® provides them with a new welding solution for metal related repair and maintenance tasks,” added Ferry. “GOWELD® is Broco’s first system used by both industrial customers and consumers. The Marines find it tough enough for the battlefield yet its ease of use makes it an ideal portable welder for weekend warriors.”

Typical tasks made easier by GOWELD® include joining metal roofing, gutters and siding on the house, fixing cattle guards, gates and fencing at the ranch, creating or repairing ornamental iron works, four-wheeler buildups and repair, adding accessories to a weekend roadster, repairing pipes, containers and conveyances at the factory, maintaining the tractor and barn at the farm, mining operations, and more. The system is designed for use in rigorous environments and a wide variety of applications where welding is more easily and successfully completed away from the shop, a welding generator or inverter power source.