Broco Underwater Cutting and Welding

Broco Underwater Cutting and Welding

Our Experience

Runs Deep

More offshore cutting is done with Broco than all competitors combined.

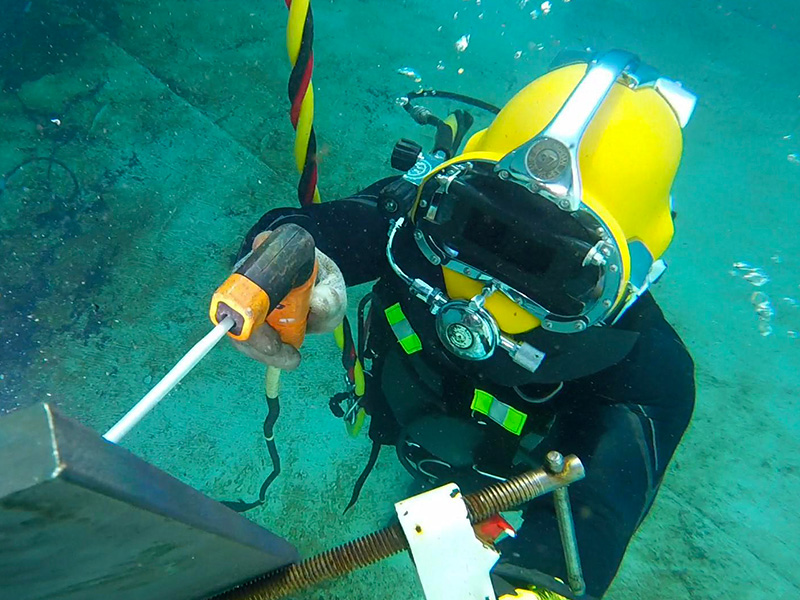

Developed by Divers for Divers

Innovation has always been at the core of Broco Underwater Cuttiing and Welding. Our first products were developed by working divers in 1975. Broco’s success in the underwater frontier is based on that foundation—a deep understanding of the requirements of the working diver. Today we continue to work with divers and world-class engineers to refine and develop products that set the standard for underwater operations.

Broco’s expertise is trusted by professional divers and underwater service companies. Our experience runs deep and so does our commitment to superior product performance and total customer satisfaction.

Proven Performance

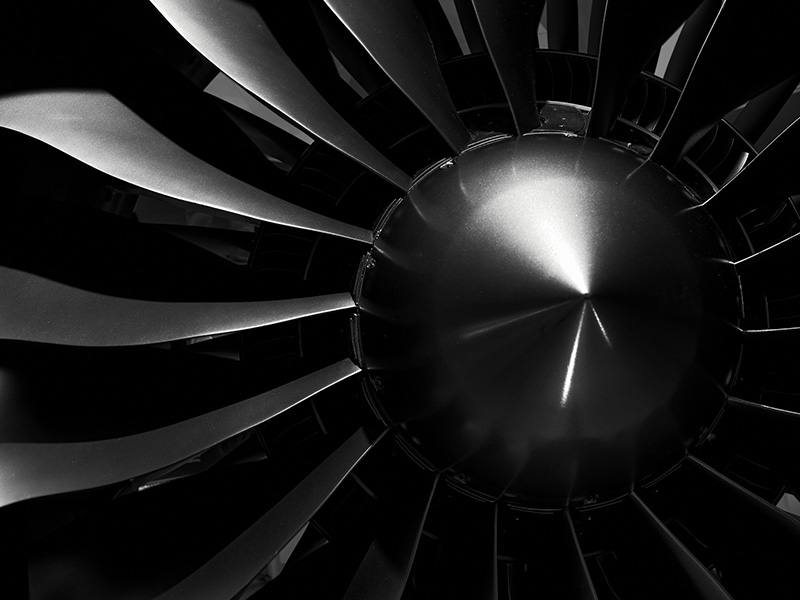

The Broco exothermic underwater cutting rod burns at an extremely high temperature. Initially patented in 1975 and updated in 1983, the Broco underwater cutting rod burns hot enough to quickly melt almost anything, including cast iron, stainless steel, brass and other ferrous and non-ferrous metals, as well as concrete. With Broco cutting rods, divers can cut sheet pile, remove tubular supports, tackle demolition projects and trim damaged props quickly.

Safer, Easier Use

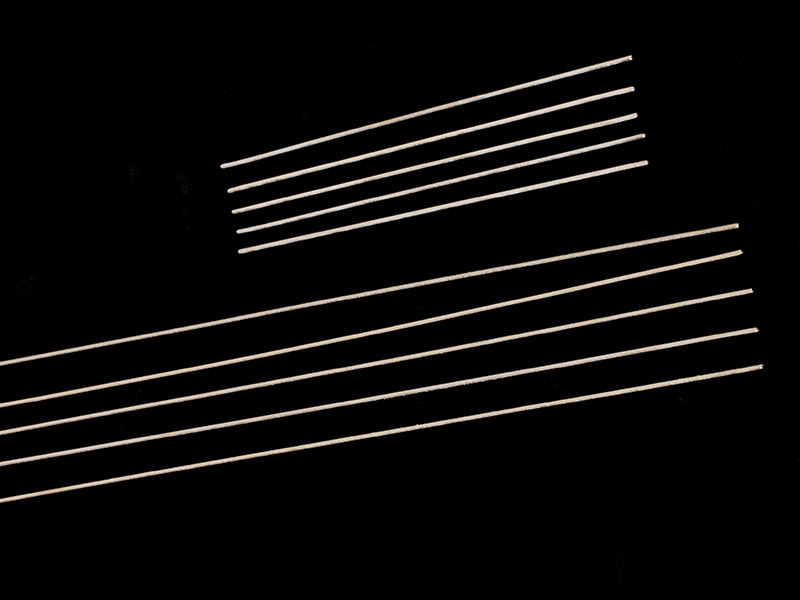

The Broco Underwater exothermic cutting torch and underwater cutting rods use only oxygen and a maximum of 150 amps to cut (compared to 300-500 amps for other systems). The Broco exothermic cutting rod has the capability to ignite readily from a 12 to 24 volt auto or marine battery up to 60 feet. The rod will continue to burn with electrical current removed until the flow of oxygen is stopped or the rod is consumed.

Approved for Navy Use

Broco Underwater products have been Approved for Navy Use (ANU) and are included in the U.S. Navy’s Underwater Cutting and Welding Manual since 1989. The 2020 revision of the manual includes Broco ultrathermic (exothermic) cutting electrodes, and the Broco BR-22 and BR-22 PLUS underwater cutting torches in Chapter 3 Underwater Cutting; and the Broco underwater welding electrode holders BR-20 and BR-21, and Broco SofTouch underwater welding electrodes in Chapter 4 Underwater Welding.

Broco® Underwater Cutting and Welding Products

Underwater Cutting

-

-

Underwater exothermic cutting rods available in multiple diameters and lengths.

Learn More

-

Sturdy polyethylene tube with reclosable cap holds 50 3/8”x18” inch exothermic cutting rods.

Learn More

-

The next generation Broco Underwater exothermic cutting torch.

Learn More

-

-

Underwater Welding

The Wet Welding Standard

Broco Underwater sets the standard for commercial wet welding electrodes. From SofTouch® certifiable mild and stainless steel electrodes and Ni-Touch nickel-based electrodes, EasyTouch® economy market electrodes, to high quality Pro-Touch® low carbon steel electrodes, Broco Underwater has the right wet welding electrodes for any underwater job. Broco specialty underwater electrodes offer engineers, diving companies, and navies around the world assurance that they are using the best when they use a Broco Underwater wet welding electrode.

Easier Certifiable Welds

Use BR-20 and BR-21 welding stingers with SofTouch and wet welding is easier and safer. Whether using the manipulative or self-consuming technique, these smooth-running electrodes require little or no pressure. SofTouch electrodes produce a hotter arc, better flow, correct penetration and a higher deposition rate. Broco’s BroCote™ proprietary formula flux coating effectively reduces hydrogen cracking and can only be found on SofTouch electrodes. EasyTouch wet welding electrodes have been formulated with performance and value in mind offering both superior strength and good weld integrity. ProTouch® delivers certifiable welds at a mid-range price.

Superior Maintenance and Repair

Since 1986 SofTouch has been listed as ANU (Approved for Navy Use). U.S Navy commands and Navy shipyards have been using SofTouch for repair and maintenance on vessels worldwide. Welding assignments on structures, vessels, in nuclear power plants and other applications require the proven performance of Broco Underwater wet welding products.

-

Comfort design underwater welding stinger. Approved for Navy Use (ANU).

Learn More

-

Lightweight, durable compression underwater welding stinger with straight handle.

Learn More

-

Low carbon steel advanced design underwater welding electrodes.

Learn More

-

Mild Steel underwater welding electrodes with BroCote™.

Learn More

-

Stainless Steel underwater welding electrodes with BroCote™ proprietary flux formulation for applications up to 33 feet.

Learn More

-

Nickel underwater welding electrodes for carbon and high tensile steel.

Learn More

-